© www.1600i.de

created 30.12.2007

Checking and repairing the ECUís relay:-

One of the most common fault which cause any of the following is usually

down to the relay 30 (the ECUís relay) being faulty:-

-

Erratic idle speed

-

Engine running badly at no-load

-

Engine stalling for no apparent reason

-

Error 0532 ECU voltage too low

-

Several errors logged by the ECU

Note: The engine could still be running

badly if the ECU relay is faulty and no

†††††††††† errors were logged by

the ECU.

If the ECU relay is suspect, then it should be removed and either

repaired or replaced.† A replacement

relay costs about 10-odd Euros or about 10-odd pounds in the UK.

The ECU relay is located in the front boot compartment on the left hand

side of the car (arrowed):-

The relay its self can be removed carefully by pulling it upwards away

from itís socket whilst holding down relay 80 (the fuel pump relay) at the same

time

.† Make sure that you do not break the relay

sockets !!

The VAG part number of the ECU relay is 165 906 381, which is shown

below:-

This ECU relay also fits the

following vehicles:- -

Type 2 T4 (Bus T4, etc.) -

Golf Mk 3 and Mk 4 -

Vento -

LT Mk 2 -

Audi A4, A6, 100 (1993) -

Audi 80 and 90 (1992-on) -

Audi Coupe -

Caddy (1996 Ė 2003) -

Passat Mk2 and Mk3, Santana -

Polo Mk2 -

and several other VWs

To fix the relay its self, you will have to remove the plastic cover

from the relay its self.† To remove it

you will need to do the following:-

-

Use two jewellerís screwdrivers (one on each side of the relay) to

gently prise off the plastic cover outwards from the relayís base.

-

Now lift up the plastic cover upwards away from the relayís base.

-

You should now be able to get at the relayís PCB.

The most common problem with the ECU relay is usually dried solder

joints on the relayís PCB.† These will

cause an intermittant (or non-existant) electrical connection between the

component(s) and the PCB its self.

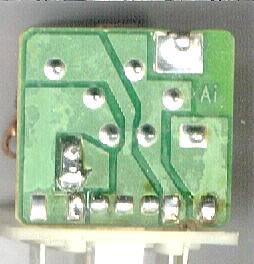

The photo below shows (in this case) where there are dried joints on the

relayís PCB, which are indicated by the red arrows:-

The solder joints shown in the photo above shows that there are several

dried joints on the relayís PCB.† Notice

the difference between the solder joint on the left hand side of the photo and

the rest of them.

Note: The relay its self may have

different dried solder joints compared to the

†††††††††† one in the photo

above.

These solder joints should now be cleaned up and resoldered.† Use a soldering iron, solder and a solder

sucker to do this.† Once those solder

joints have been redone, the relayís PCB should now look like the one shown in

the photo below:-

Now compare the two different photos and notice how shiny and complete

the solder joints are.† This should now

fix the ECU relay problem.

Now refit the relay back into itís relay socket, connect up your

diagnostics kit and start the engine.†

Now read the fault codes from the ECU and erase them.† The engine should then run normally.

This document has been translated (in my own words) by Phil Ade,

Saturday 3rd November 2007.